Maintaining your vehicle’s belts and hoses is crucial for ensuring the smooth operation of your car.

These components play an important role in your engine’s performance and cooling system. Neglecting them can lead to serious problems like overheating or even engine failure. This guide will show you how to inspect your vehicle’s belts and hoses for wear and tear, helping you avoid costly repairs in the future.

Understanding the Role of Belts and Hoses

Belts

Your vehicle’s belts, such as serpentine belts, V-belts, and timing belts, play a critical role in powering various engine components. The serpentine belt, for instance, drives multiple peripheral devices including the alternator, power steering pump, and air conditioning compressor. Timing belts synchronize the rotation of the crankshaft and camshaft, ensuring that the engine’s valves open and close at the proper times during each cylinder’s intake and exhaust strokes.

Hoses

Hoses, like coolant and heater hoses, are important for moving fluids through the engine.

Coolant hoses carry antifreeze between the engine and the radiator to keep the engine cool. Heater hoses send hot coolant to the heater core to warm the inside of the car.

Keeping these hoses in good shape helps prevent leaks and keeps your car’s heating and cooling systems working well. For more tips, check out our guide on how to maintain your car’s cooling system.

Tools Needed for Inspection

Before starting your inspection, gather the necessary tools:

- Flashlight: Helps you see clearly in tight or dimly lit areas around the engine.

- Gloves: Protect your hands from sharp edges or hot parts.

- Small mirror: Useful for checking hard-to-see spots.

- Safety goggles: Keep your eyes safe from dust, debris, or fluids.

- Rag or cloth: Wipe away dirt, grease, or fluids to get a clear view of the belts and hoses.

- Belt wear gauge: If available, use a belt wear gauge to measure the condition of your belts.

Make sure your vehicle is turned off and has had time to cool down before you begin to avoid burns from hot engine parts. Staying safe is essential when inspecting belts and hoses. For more tips on car safety, check out our seasonal safety advice.om hot engine components.

Visual Inspection of Belts

Look for Cracks and Fraying

Examine the belts closely for any visible cracks, fraying, or splits on the surface. These are common signs of aging and wear that can lead to belt failure. If you notice extensive cracking or fraying, it’s a clear sign the belt should be replaced right away to prevent sudden breaks while driving. For more help with maintaining your car’s key components, check out our engine repair services to ensure everything stays in top shape.

Check for Glazing

Glazing happens when a belt’s surface becomes shiny or slick, usually due to too much heat or friction.

A glazed belt can slip, making it less effective at driving engine components. If you notice a glossy or polished appearance on the belt, it’s a sign that the belt is worn out and should be replaced. For more tips on keeping your engine in good shape, visit our engine maintenance guide.

Twist the Belt

Gently twist the belt to check its underside. Look for signs of wear like separating layers or any embedded debris. These can weaken the belt’s structure and increase the risk of breakage. A weakened belt can fail at any time, so it’s important to address these issues right away. For more guidance on keeping your car in top condition, take a look at our preventative maintenance guide.

Visual Inspection of Hoses

Check for Soft Spots and Bulges

With the engine cool, gently squeeze the hoses near the clamps and along their entire length.

They should feel firm but still flexible. If you notice soft or mushy spots, this could mean the hose is damaged or weakened internally. Bulges are another warning sign that the hose has lost its strength and may burst under pressure. Replacing damaged hoses can prevent major engine problems. For more help with maintaining your vehicle, check out our guide on understanding your car’s maintenance schedule.

Inspect for Cracks and Leaks

Look for visible cracks, especially around bends and connection points. Leaks often leave behind dried coolant residue, which can appear as white, light green, blue, or pink streaks. If you notice any cracks or leaks, it’s essential to replace the hose right away to prevent further damage. For more help with your vehicle’s cooling system, visit our page on coolant flush and refill services.

Examine Connection Points

Check the clamps and connections for a secure fit.

Loose or corroded clamps can lead to leaks and cause the system to lose pressure. Make sure the hoses are tightly clamped to prevent coolant loss and maintain the correct pressure in the system. For more guidance on keeping your vehicle in good condition, visit our page on radiator replacement services to learn how to avoid overheating issues.

Testing Belt Tension

Manual Tension Test

Press down on the belt to check its tension. It should have a slight give but remain taut. If the belt feels too loose or too tight, it might need an adjustment or replacement to ensure proper function. Ignoring improper tension can lead to premature wear or failure.

Using a Tension Gauge

For a more accurate reading, use a belt tension gauge. Refer to your vehicle’s manual for the recommended tension specifications and adjust as necessary. If you’re unsure about adjustments, consider consulting a professional. For more information on keeping your car in top shape, visit our page on tune-ups.

Common Signs of Wear and When to Replace

Common signs that a belt needs replacement include:

Squealing Noises Under the Hood

One of the first signs that a belt may need replacement is a high-pitched squealing noise coming from under the hood. This noise is often caused by a loose or worn-out belt, which can slip on the pulleys, resulting in that characteristic squeal. If left unaddressed, this issue can lead to a complete belt failure, leaving essential components like the alternator or power steering pump without power. If your vehicle is making strange noises, you may want to learn more about our sensor replacement services, which could also be a contributing factor.

Power Loss and Engine Performance Issues

Another clear sign of a failing belt is a noticeable loss of power or overall engine performance issues. The belt is responsible for driving multiple components, such as the alternator, water pump, and power steering. When the belt is worn or damaged, these components may not receive the power they need to function properly, leading to reduced engine performance or even overheating. For help diagnosing these types of issues, see our guide on engine diagnostics.

Visible Cracks, Fraying, or Glazing

Visually inspecting the belt can reveal additional clues that it needs replacement. If you notice visible cracks, fraying, or glazing on the surface of the belt, it’s a strong indicator that the belt is reaching the end of its lifespan. Glazing often occurs when the belt has been exposed to excessive heat or friction, creating a shiny surface that causes the belt to slip and lose its effectiveness. Cracks and fraying are other common signs of wear and tear that weaken the belt’s structure. For more tips on keeping your vehicle safe, read our car care guide.

Loose Belts and Tension Issues

Belts that are too loose or appear to be slipping often indicate that the tension needs adjustment. A loose belt can cause misalignment, leading to vibration or wobbling during engine operation. This can affect the performance of the engine’s various components and result in further damage if not corrected. A failing belt tensioner can lead to uneven belt wear, causing the belt to fail prematurely. For more insights on steering and suspension-related issues, check out our steering and suspension services.

Unusual Smells

You might also notice unusual smells, such as burning rubber, coming from your engine. This smell is often a result of the belt slipping or overheating due to friction. A belt in this condition should be replaced immediately to avoid more significant damage to the engine. To make sure your vehicle is ready to handle these types of issues, see our pre-purchase vehicle inspections to get expert insight into your car’s condition.

Belts typically need replacement every 60,000 to 100,000 miles, but check your vehicle’s manual for specific recommendations.

Replace hoses if you notice:

Coolant Leaks or Low Coolant Levels

If you notice coolant leaks or your coolant levels are consistently low even after regular top-offs, this could be a sign of a failing hose or another issue in the cooling system. Leaks often occur at the connection points where the hoses meet the radiator or engine, so it’s essential to inspect these areas closely. Ignoring these signs can lead to more severe issues such as overheating or engine damage. For more tips on keeping your car’s fluids in check, visit our guide on the benefits of regular fluid checks.

Overheating Engine

An overheating engine is another common sign that your hoses or other cooling components are failing. Coolant hoses that are cracked, blocked, or leaking can cause a drop in coolant levels, leading to an overheated engine. If your vehicle begins to overheat, it’s crucial to address the issue immediately to prevent further damage. For additional advice on engine care, consider reading our guide on engine damage repair to keep your vehicle running smoothly.

Visible Cracks, Soft Spots, or Bulges

During your inspection, look for visible cracks, soft spots, or bulges in the hoses. These signs indicate that the hoses have lost their structural integrity and are likely to fail soon. A soft hose means it has weakened internally, while bulges suggest pressure issues that can lead to a burst. If you notice any of these warning signs, it’s time to replace the hose immediately.

Hoses should generally be replaced every four years or sooner if any signs of wear are present.

Preventive Maintenance Tips

Regular Inspections

Perform regular inspections of belts and hoses every oil change or at least every six months to catch early signs of wear.

Coolant Flushes

Regularly flushing and replacing coolant according to your vehicle’s maintenance schedule helps prevent electrochemical degradation, which can weaken hoses.

Read More: Role of Coolant in Car’s Performance

Using Quality Parts

When replacing belts or hoses, opt for high-quality parts designed to resist wear and electrochemical degradation. Look for labels indicating they meet or exceed OEM specifications.

Conclusion

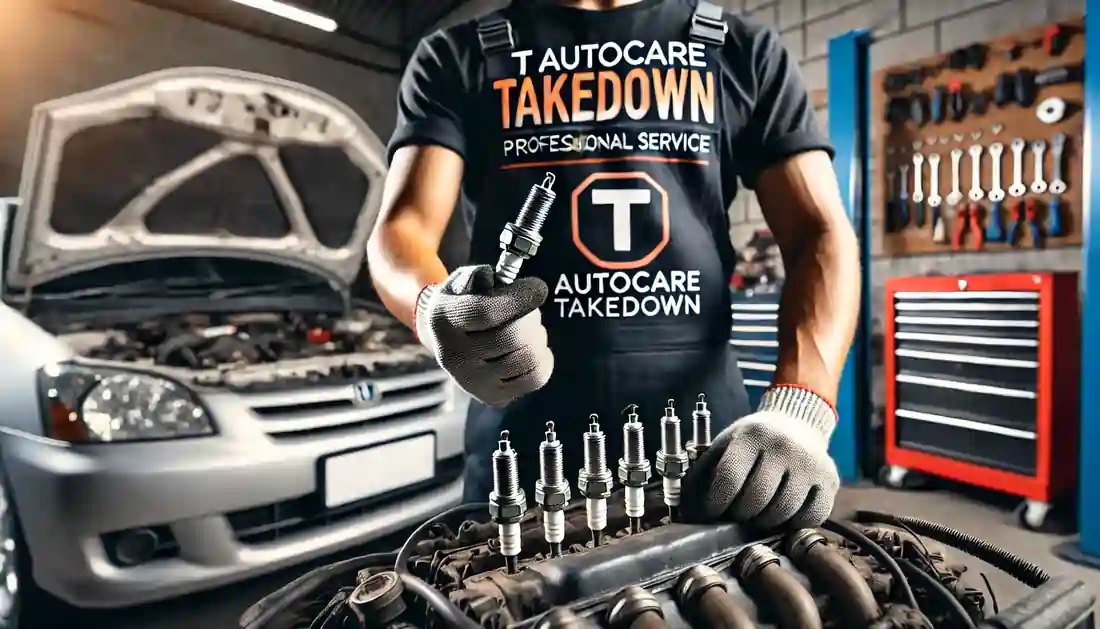

Regular inspections of your vehicle’s belts and hoses are essential for preventing breakdowns and costly repairs. If you’re unsure about performing these checks yourself, or if you spot any signs of wear, visit T Autocare Takedown in Broken Arrow, OK. Our expert mechanics can provide thorough inspections and replacements to keep your vehicle running smoothly.

Schedule an inspection or maintenance service at T Autocare Takedown today. For the best in Broken Arrow auto repair, choose T Autocare Takedown.

Contact us at (539) 367-3738 or visit us at 1501 W Detroit St, Broken Arrow, OK 74012. New customers get a 20% discount on their first repair.

By following this guide, you can help ensure your vehicle remains in optimal condition and avoid unexpected breakdowns. Happy driving!